Precision Machining

High precision machining is a manufacturing process that turns raw materials into precise components with very tight tolerances and high-quality surface finishes. Precision machining processes normally are turning, milling, drilling, boring, gear cutting, honing, grinding and other operations. As a special process in precision machining, heat treatment that typically encompasses quenching, tempering and carburizing can be employed to improve the mechanical function of parts and components.

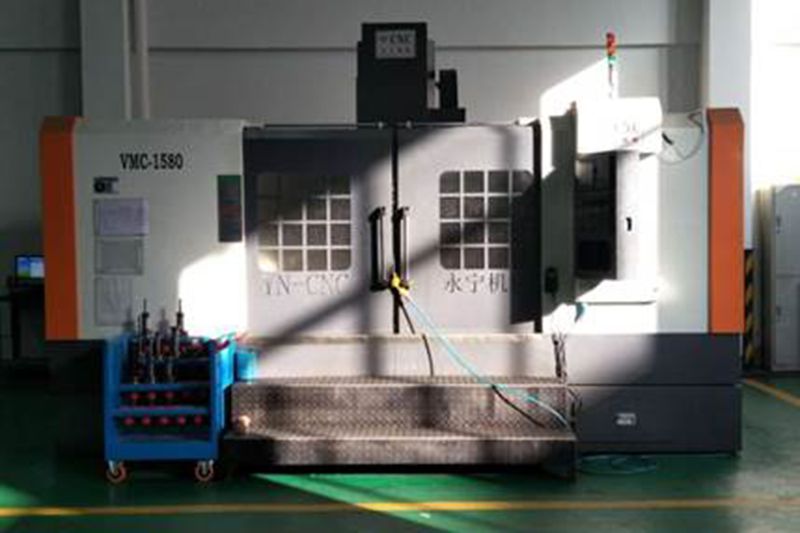

In the precision machining process, computer numerical control (CNC) technology is generally utilized to automate the operation through a program, thus enabling the special designs to be converted into exact shapes and sizes.

At Hongyan Hang we offer high precision machining services to help machine builder OEM customers and system integrators produce precise components used in a multitude of industry sectors. We are your trusted one-stop-shop to eliminate your cumbersome processes of purchasing raw castings, secondary machining and inspection. We have a complete line of CNC machine tools from world's renowned brands such as Haas, Mazak and Doosan to ensure the machined parts meet your required tolerance and surface quality.

Hongyan Hang is a company specialized in providing precision manufacturing services to product manufacturers who require custom precision metal parts. We can help customers design, engineer and mass production of various precision metal parts and components with our complete capabilities of investment casting, CNC machining, sand casting, die casting and 3D printing.