Sand Casting

Sand casting, also referred to as sand molding casting because it is a metal casting process using compressed sand as the mold material. The process involves the pouring of molten metal into the sand mold where it solidifies in the mold cavity. The versatility of sand casting has been proven through centuries of development, it is the most widely used metal casting method.

Many factors have to be taken into consideration for producing high-quality sand castings, the designers have to pay careful attention to the shaping requirements and dimensional needs. Sand casting can be used to produce metal parts in a wide range of sizes and designs, and a huge variety of metals and alloys can be processed.

- Pistons and valves

- Blowers and impellers

- Cams, bearings and bushings

- Electronic equipment

- Medical equipment

- Bearings

- Engine blocks and manifolds

- Transmission cases

- Cylinder heads

- Crankcases

- Oil pans

- Pump body

- Bolts, nuts and screws

- Gears

- Mining machine parts

- Automobile parts

- Trailer parts

- Chassis parts

- Water jackets

- Cast iron

- Cast steel

- Alloy steel

- Stainless steel

- Aluminum alloy

- Brass alloy

- Low cost: sand casting tooling and equipment costs are low in comparison with other metal manufacturing processes;

- Wide range of metals: more than 60% of metal castings are produced by sand casting;

- High versatility: sand casting can produce precise metal components in any sizes and complex shapes;

- High flexibility: different sand molding materials can be applied, such as resin sand and wet sand;

- Less waste: scrap metal can be recycled;

- Short lead time: ideal for production requiring short cycle;

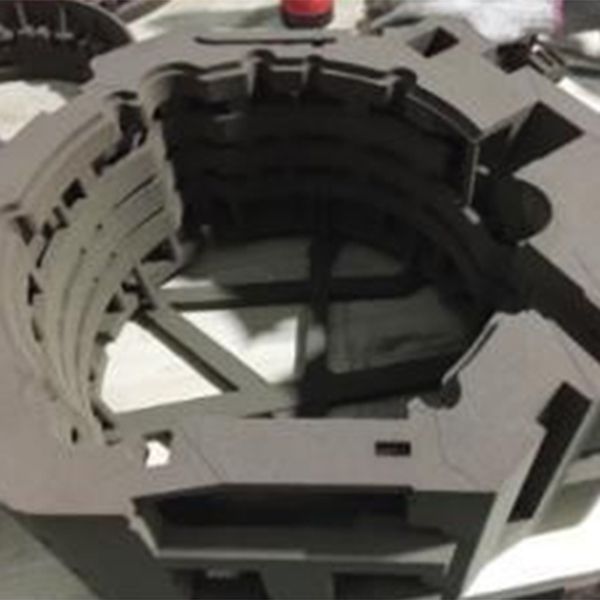

Sand casting is useful for shaping and producing an extensive range of precise metal parts. Some small sand casting parts include connecting rods, crankshafts, gears, pulleys, propellers, etc. And large sand casting parts include engine blocks, transmission cases, cylinder heads, engine manifolds, etc.

Sand casting for motor housing

In addition to our sand casting service, Hongyan Hang also offers other services including investment casting, precision machining, die casting and 3D printing to meet customers' needs of precise parts manufacturing and prototyping. Our capabilities help our customers reduce costs, increase efficiency, save valuable resources and gain the visibility into its supply chain, as well as ensure the quality and reliability of products.

Hongyan Hang is a company specialized in providing precision manufacturing services to product manufacturers who require custom precision metal parts. We can help customers design, engineer and mass production of various precision metal parts and components with our complete capabilities of investment casting, CNC machining, sand casting, die casting and 3D printing.